Formulating around the environmental impact of poultry products

- Home

- Formulating around the environmental impact of poultry products

There is an increasing interest from producers, processors and consumers for the consideration and insight of the environmental impact of poultry products. Various environmental assessments have been researched over the years from carbon sequencing to nutrient surplus per hectare, however they differ greatly in their purpose and methodology.

Life cycle assessment (LCA) overcomes many of these limitations and disconnected approaches. LCAs can provide data to give sufficient environmental information throughout an animal’s life, to give environmental impact per kg of poultry product. Part of this evaluation and a large proportion of the contribution comes from feed ingredients with varying metrics including, but not limited to, carbon emissions, water consumption and eutrophication potential.

Increasingly, the use of the GFLI database and the inclusion of LCA data of commercial feeds have been researched. The GFLI database is a global reference database that uses and differentiates the LCA results for macro feed ingredients. Factors such as geographic location, processing and transport are used in the calculation process. This publicly accessible database harmonises the assessment and benchmarking of the environmental footprint for feed ingredients. Given the wide variety of specialty feed ingredients, types, and manufacturing processes, capturing feed additives in a database is a challenge. The database is currently running a pilot study for branded datasets which is defined as “’Lifecycle inventory/impact assessment (LCI/A) data for a feed ingredient marketed under a certain brand and owned by a company or other entity’’. Enabling the collection of data in micro raw materials not currently in the GFLI database such as feed additives and co-products. This pilot is tackling the shortfall of data on micro ingredients, although these ingredients only account for a small proportion of the overall feed GWP, it is important to have a full accurate dataset.

Practical application of the GFLI data allows feed producers to monitor their environmental impact and share this with poultry farmers. Global warming potential (GWP) (kg CO2e) from the database can be used in the formulation system, set up in a similar way as a nutrient with each raw material contributing to the overall GWP of the diet.

In the last couple of years, we as nutritionists have had a growing number of requests to evaluate and implement low GWP rations, whilst maintaining bird performance. This requires innovative thinking with a greater understanding of available feed ingredients, feed mill limitations, the nutritional requirements of modern genetics and possible implications for bird performance and therefore overall cost of production in terms of GWP and economics.

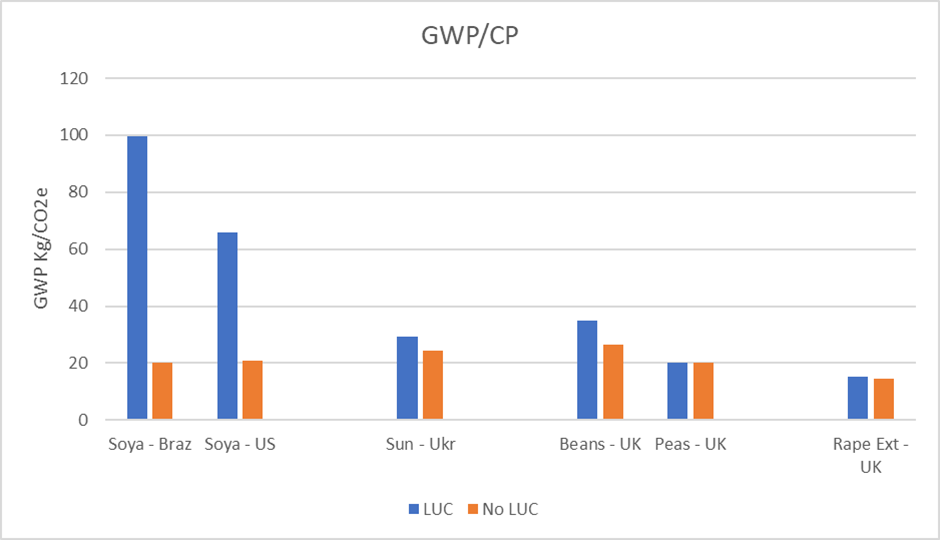

As mentioned, the implications of GWP formulations are multifactorial. The main implications of low GWP rationing relates to raw material usage and availability, nutritional, performance and cost. When bringing new raw materials into a feed formulation, we must at first understand their nutritional value and how this compares against those currently utilised. Soyabean meal (SBM) for instance is the industry’s main protein source, is nutritionally well understood, highly digestible and has an amino acid profile closely aligned to the bird’s requirements. All whilst being freely available, in high volume at cost effective prices. However, it has one of the highest GWPs of any raw material used within poultry formulations (Fig. 1). Using alternative protein sources such as sunflower, field beans or rape meal could reduce the GWP of the ration, but their individual nutritional values are quite different to SBM.

Nutritionally, replacing SBM with alternatives such as sunflower and rape meal could have the advantage of increasing the insoluble fibre in the ration for particularly commercial layers and breeders. The digestibility of sunflower and rape meal is generally lower than that of SBM, which requires nutritionists to balance rations with additional single amino acids, to limit any increase in crude protein as rations are formulated to the digestible levels of individual amino acids. Excess crude protein can lead to higher nitrogen excretion and cause gut health challenges as undigested protein can cause proliferation of harmful bacteria in the gut, which can challenge bird health and performance. Similarly, protein alternatives tend to be lower in energy than SBM, which leads to more added oil in the ration, this may have negative effects on the pelleting process and therefore physical quality of the feed. As with proteins, using alternative sources of oil to soya oil, requires nutritional consideration. Rape oil has less linoleic acid content and sunflower oil is poorly available for use in UK poultry rations, these have the potential to impact egg size in laying birds.

Often the most restrictive factor for formulating of lower GWP rations would be the cost. Generally, formulating to lower GWP levels would be more expensive than the least cost approach which is commonly used within the industry. The current economic climate with inflation makes it harder to pass on the cost of lower GWP rations, as this raises food prices to the public.

Overall, more commercial scale experience is needed for the industry to gain greater confidence in lower GWP rations. Although we as nutritionists have the tools and expertise out there to drive innovative change and meet the demands and expectations of consumers. This is well evidenced by lines of more environmentally conscious poultry products hitting the supermarket shelves.

To wrap up, although outcomes are often influenced by social, environmental, and economic decisions, will there be a further shift in diet formulations within the animal industry towards a low GWP rations in the future?

Figure 1 GWP per 1% crude protein of typical protein sources used in poultry diets. Calculations based on GFLI database and Premier Atlas.

Researched & written by Lottie Farrow & Alex Kemp, Poultry Nutritionists, Premier Nutrition